-

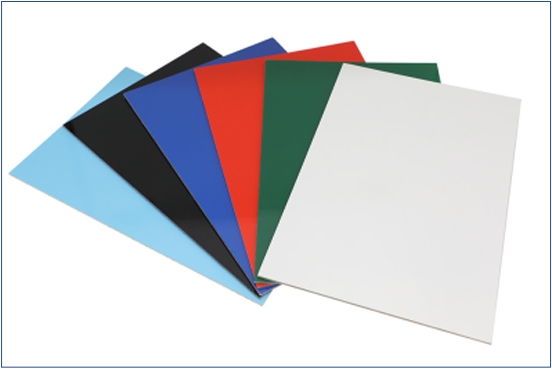

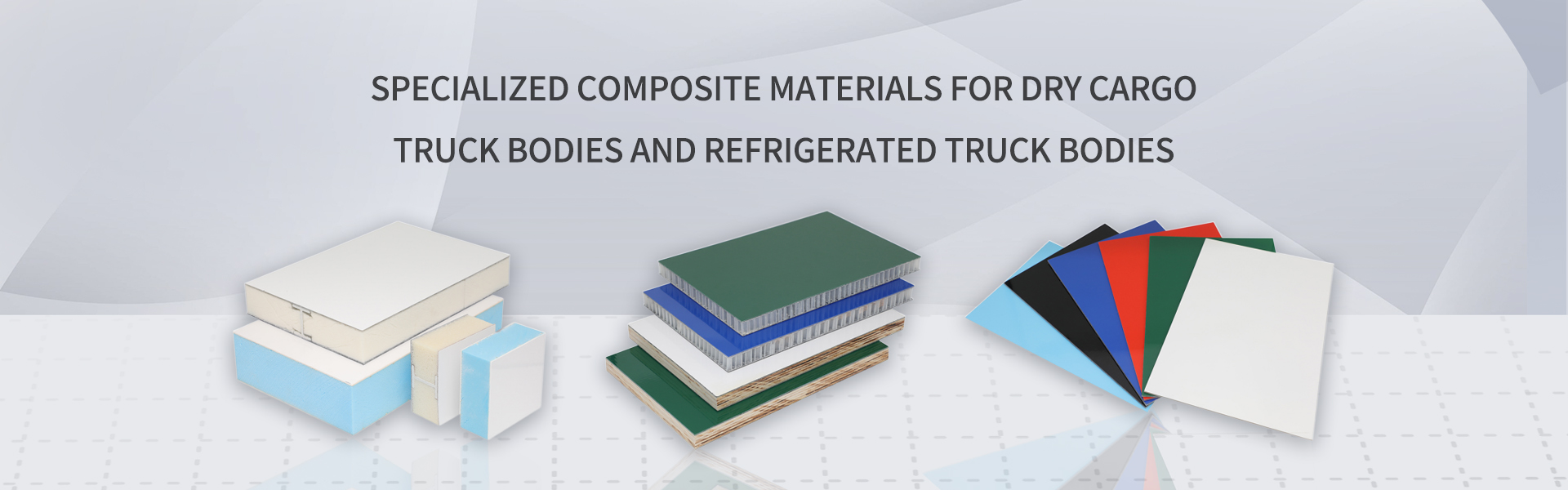

FRP Sheet

FRP sheet is made of high strength fiberglass chopped strand mat, high strength fiberglass woven roving and high quality unsaturated polyester resin. The gel coat on surface is food grade and FDA approved. FRP sheet is mainly used for inner and outer surfaces of FRP composite panels or roofs of dry cargo truck bodies.

• Thickness: 1.0mm-3.0mm

• Max Width: 3000mm

• Length: 80-100 meters per roll or as required

• Color: RAL system or as customer required

More Details

-

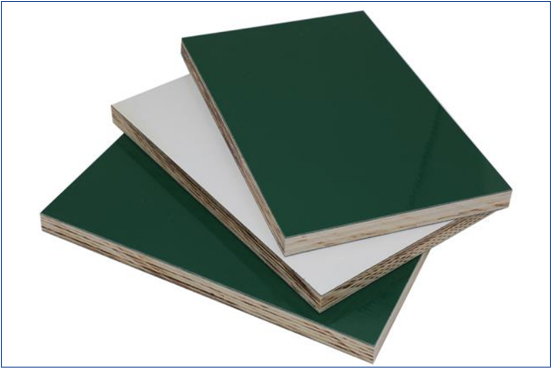

FRP Plywood Composite Panel

FRP plywood composite panel is made of prefabricated FRP sheet, high strength fiberglass woven roving and water-proof plywood, then bond them together by vacuum high pressure. It is essentially a sandwich panel, FRP sheet for the both sides and plywood for the core. The gel coat on surface is food-grade and FDA approved. Customized high-strength aluminum profiles and other structure components can be provided for easy and fast assembly.

• Thickness: 15mm / 18mm / 21mm

• Max size: 16500mm long and 3000mm wide

• Color: RAL system or as customer required

More Details

-

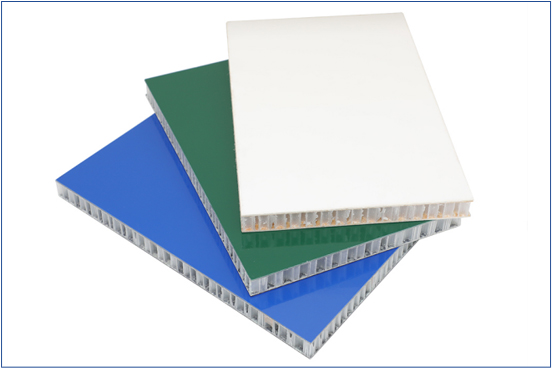

FRP Honeycomb Composite Panel

FRP honeycomb composite panel is made of prefabricated FRP sheet, high strength fiberglass woven roving and plastic honeycomb, then bond them together by vacuum high pressure. It’s essentially a sandwich panel, FRP sheet for the both sides and plastic honeycomb for the core. The gel coat on surface is food-grade and FDA approved. Customized high-strength aluminum profiles and other structure components can be provided for easy and fast assembly.

• Thickness: 15mm / 18mm / 21mm

• Max size: 16500mm long and 3000mm wide

• Color: RAL system or as customer required

More Details

-

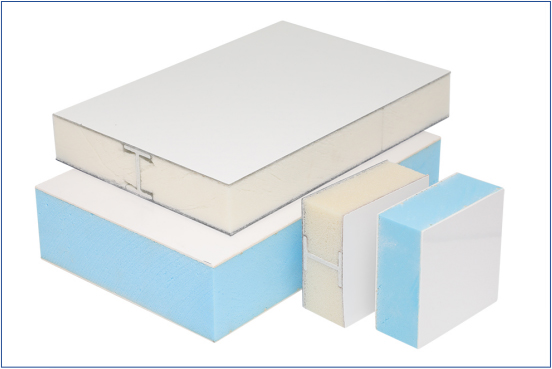

FRP Foam Composite Panel

FRP foam composite panel is essentially a sandwich panel, FRP sheet for the both sides and PU/XPS/PET for the core, bonded by vacuum high pressure. The gel coat on surface is food-grade and FDA approved. Customized high-strength aluminum profiles and other structure components can be provided for easy and fast assembly.

• Foam Core: PU/XPS/PET

• Thickness: 30mm/45mm/70mm/85mm/105mm/130mm

• Max size: 16500mm long and 3000mm wide

• Color: RAL system or as customer required

More Details

Founded in 1996, Maxtone is the first professional manufacturer in China which has been specialized in fiberglass composite panels for more than 25 years, with the largest production scale and most advanced technology and equipment. In 2018, Maxtone became a wholly-owned subsidiary of Zhejiang Wazam New Materials (stock code: 603186).

Our plant covers an area of 53,292 square meters. In order to produce higher-quality composite panels, we introduced advanced equipment and technology from America, Australia and Sweden. The composite panel is essentially a sandwich panel, fiberglass reinforced plastic for the both sides and waterproof plywood/PP honeycomb/PU foam/XPS foam/PET foam for the core, then bond them together by vacuum high pressure. There are many advantages of our composite panels, for example, high surface finish, high UV resistance and weathering protection, low coefficient of thermal expansion, easy to clean and easy to repair, anti-aging and anti-corrosive, long service time, high strength, light weight and so on.

More Details

-

1996Since

-

100+Employee

-

600,000㎡ +Annual Production Capacity

Professional Team

Professional Team

Any inquiries will be replied within 24 hours. Free samples are available. We can offer high quality truck body panels at very reasonable price. And we always keep our promises, deliver the products on time, no worry about the delay.

Quality Assurance

Quality Assurance

We had passed the certification of ISO 9001 quality management systems. Quality Control is always focused on strictly in our daily work. We are familiar with the quality standards demanded by overseas customers. All products would be strictly inspected by quality supervisors before delivery.

Customized Solutions

Customized Solutions

We have the very excellent R&D team with years of experience, which could provide customized solutions for different applications such as dry freight truck bodies, refrigerated and insulated truck bodies, according to clients’ specifications and requirements.

Perfect After-sales Service

Perfect After-sales Service

We can provide 12 months warranty for our composite panels, and 6 months warranty for the parts and accessories supplied. Full set of documents or guidance will be provided to help you assemble CKD truck body kits quickly and easily.

+86-514-82060713

+86-514-82060713

No. 7 Xinyi Road, Weiyang Development

No. 7 Xinyi Road, Weiyang Development